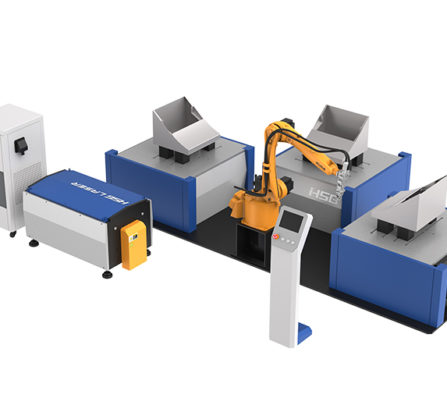

Description

Feature:

- Continuous wave output, excellent welding compactness with high intensity;

- Concentrated laser heat, rapid welding speed and small thermal deformation

- Multi-station cooperative work can be designed to realize loading and unloading alternately thus to enhance productivity;

- Customer could design fixture/clamp combination accordingly with flexible working platform

- The equipment has high electro-optic conversion efficiency requiring no additional welding material. And the cost is low;

- Basically, the core components are maintenance-free thus the running costs is low.

- FIBER laser source from 500w to 4.000w

- Welding wire adding possibility to fill gaps up to 1.8mm p

- KUKA robotic arms with 6 joints for ± 360° movemen.

- Proximity sensor for the laser head

- Water Chiller included

- Industrial computer, remote and software included

- Electronics – Schneider and Omron

- Suitable for car manufacturing lines, kitchenware, medical tech etc

Optional:

- Protection cover

- Multiple tables of multiple size

- Machine can be personalized according to each client production cycle

Welding sample:

Welding of any ferrous and non-ferrous metal. The welding power is twice the required cutting power of the same metal.

At 2,000w is suitable for welding with or without wire addition: 8mm Steel, 4mm Stainless Steel, 4mm Aluminum, 3mm Brass and 2mm Copper

Reviews

There are no reviews yet.